home | India | Ikat | tie-dye | embroidery | block printing | carpets | kalamkari telia rumal | natural dyes | special weaves | travel | bibliography

|

Hand spinning is still being carried out in limited areas of India for KHADI, the hand spun and hand woven cloth encouraged by Ghandi as a protest at village level against the British mill-made fabric imported into India. Gandhi encouraged everyone to do a little spinning every day and even to burn their foreign clothing. Eventually the handspun hand woven fabric known as Khadi took over even at the professional level. |

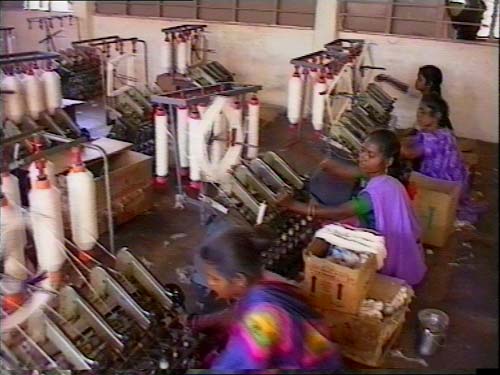

| The government has set up the Khadi boards which helps spinners and weavers in various ways. They help with supply of material, marketing and development of equipment. Because of the volume of yarn needed by the hundreds of thousands of weavers and also the need for women to earn a wage’ they have developed a machine that can spin and fill 8 bobbins at a time. The only human involvement is for a person to turn the handle. This too could be automated but would take away employment. However calling fabric woven from this yarn as khadi is certainly stretching a point. However the price charged for this fabric as compared to the fabric from Ponduru certainly distinguishes one product from another. |  |

|

|

|

|

This

Orissan fisherman is spinning mill-made cotton yarn bought at

the market to strengthen it for making and repairing fishing nets.He

works while walking along the road. We saw other fishermen catching

fish with woven baskets |

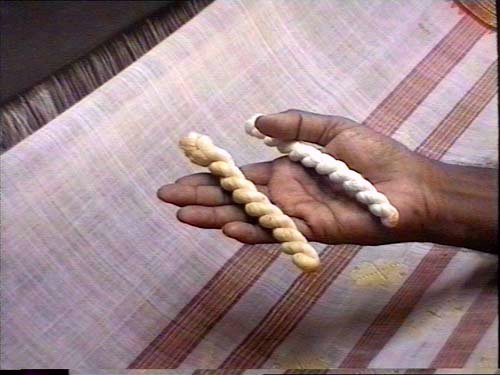

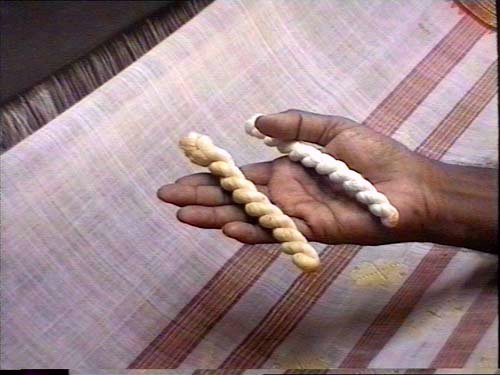

The

inner filament is reeled off the cocoon by hand and spun on the thigh,

before twisting onto a reel. Between 6 and 12 cocoon filaments are plied

together creating a fine thread suitable for weaving |

|

|

The remaining fibre comes from the peduncle which attaches the cocoon to the tree. This tough material is soaked in water, then pounded before spinning by drop spindle. The resulting yarn is coarser and darker than the others. |

|

|

The beautiful fabrics created from these yarns represent an enormous amount of work, but are greatly valued. Notice the sheen on the yarn which is created by sizing the yarn with gum arabic. |  |

|

Most silk in India is factory reeled. This silk is cultivated Bombyx mori raised by farmers in Kanataka on Mulberry leaves placed in large woven baskets.T he cocoons are carried to auction houses where many small factory owners buy lots of 10 kilos for processing..The cocoons are boiled to kill the larvae, preventing the filaments being broken by an emerging moth. Generally about 6 filaments are reeled together to create a thread, which then may be plied with another thread. top |